橋梁支承用CRゴムコンパウンド

Jia shi maは専門のサプライヤーであり、橋軸受用のCRゴムコンパウンドを持っており、高性能混合接着剤の橋軸受用途のための専門的な研究開発です。クロロプレンゴムをベースに各種添加剤を配合し、精密な混合工程を経て作られています。大きな圧力がかかってもしっかりと梁を支えることができます。温度変化に対してもスムーズに伸縮し、様々な応力を吸収します。ご不明な点がございましたら、お気軽にお問い合わせください。

お問い合わせを送信

The CR Rubber Compound for Bridge Bearings produced by our Jiashima factory is a "specially formulated compound rubber for making Bridge Bearings". Its core value lies in "providing a reliable elastic connection between the superstructure and substructure of the bridge through its excellent weather resistance, aging resistance and mechanical strength, to bear loads, adapt to deformations and absorb vibrations." As a "functional engineering material", it quietly safeguards the safe operation of Bridges throughout their decades-long service life.

Feature

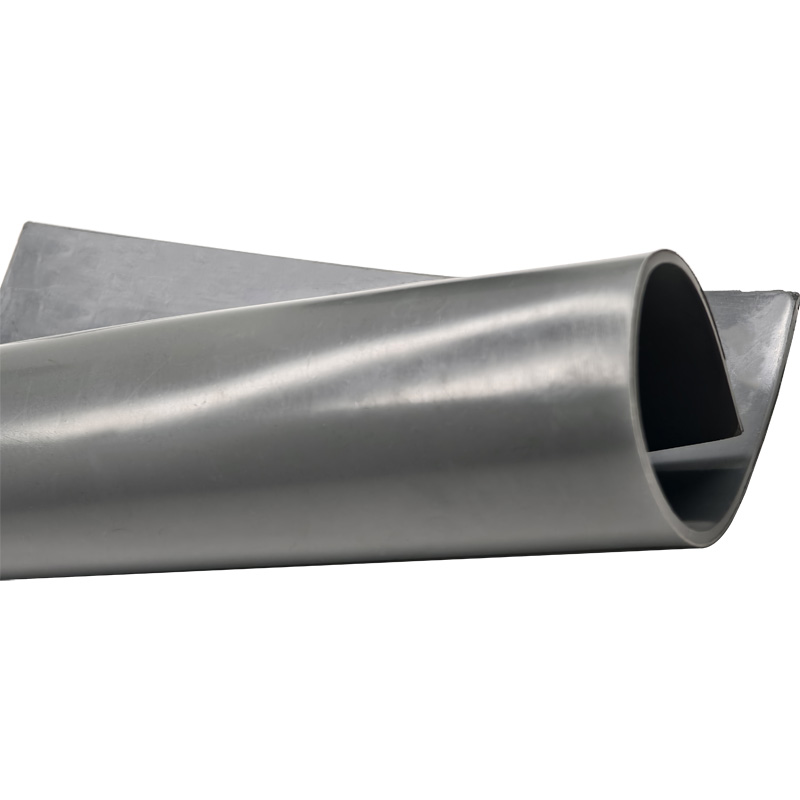

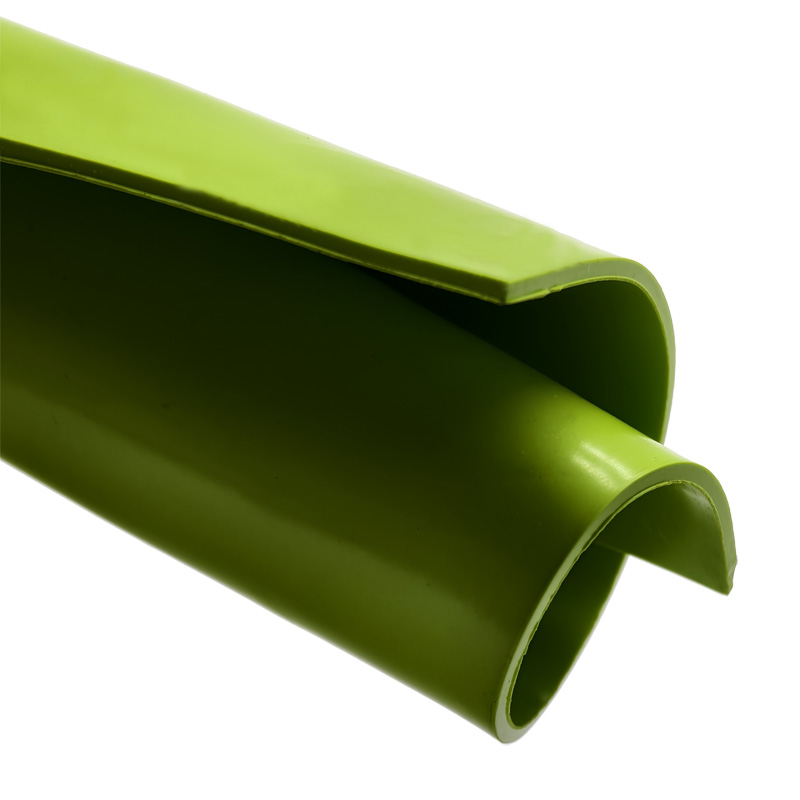

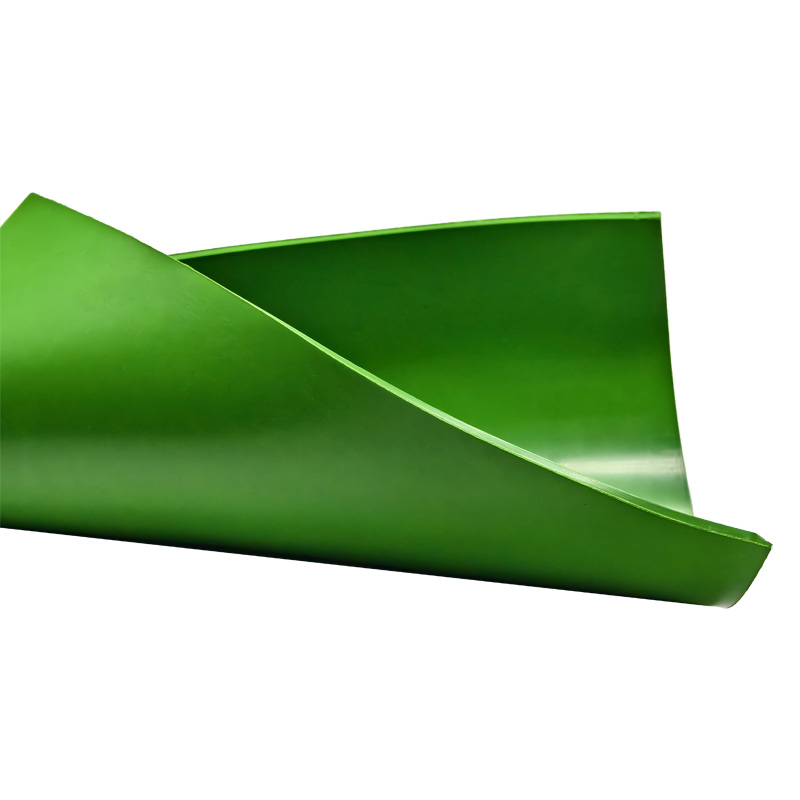

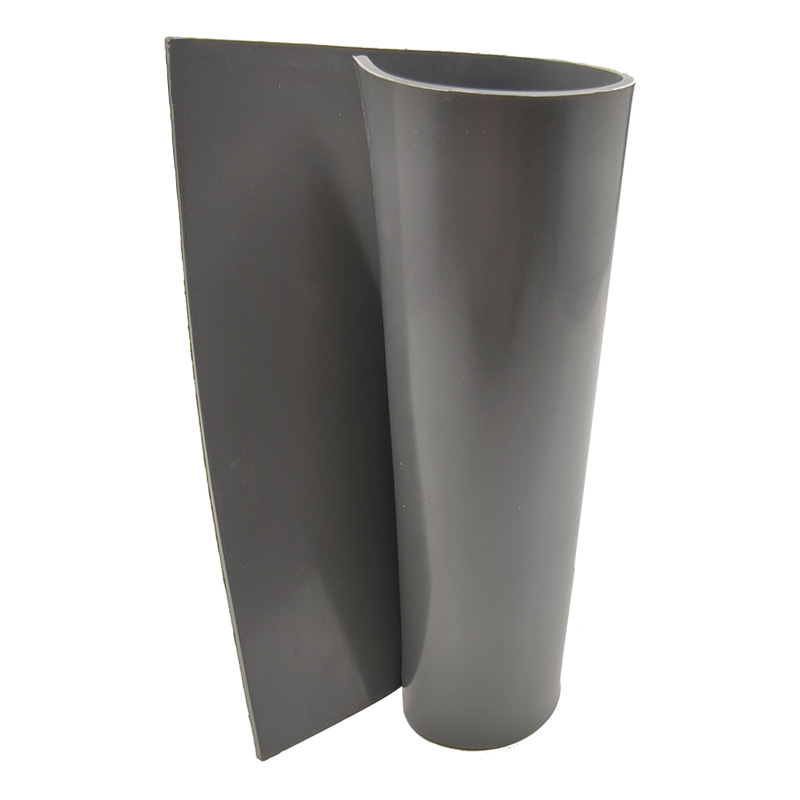

The CR Rubber Compound for Bridge Bearings gives the impression of being "tough" and "stable". It comes in rolls or blocks, usually dark black in color, uniform in texture, and free of visible impurities or bubbles to the naked eye. Press it with your hand and you can feel that it has both the elasticity of rubber and an inherent sense of firmness. It gives off a faint rubber smell characteristic of industrial materials rather than a pungent chemical odor.

Structure

The structure of this CR Rubber Compound for Bridge Bearings is "a complex chemical formula system, not a simple physical form". It takes chloroprene rubber (CR) as the base material and is thoroughly mixed with various additives such as carbon black, vulcanizing agent, antioxidant and plasticizer through an internal mixer.

Product Parameter

| Product Name: | CR Rubber Compound for Bridge bearings |

| Material: | CR |

| Size: | Flaky |

| Color: | All colors from the Pantone color card |

| Packing: | Pack in cartons first and then on pallets. |

| Sample time: | 1-2days |

| Mass-production time: | Less than 5 days |

| Warranty: | Can be stored for more than 1 year if not applicable |

| Application: | Bridge bearings |

Why choose us?

Because our company is "a professional manufacturer specializing in the research and development and production of high-end engineering rubber materials". We fully understand the extreme requirements for material performance and the zero-tolerance attitude in bridge engineering. We have a complete technical chain ranging from formula research and development, raw material testing, blending to finished product performance testing, and can provide you with "in-depth" services from material selection to technical support.